Case Hardening

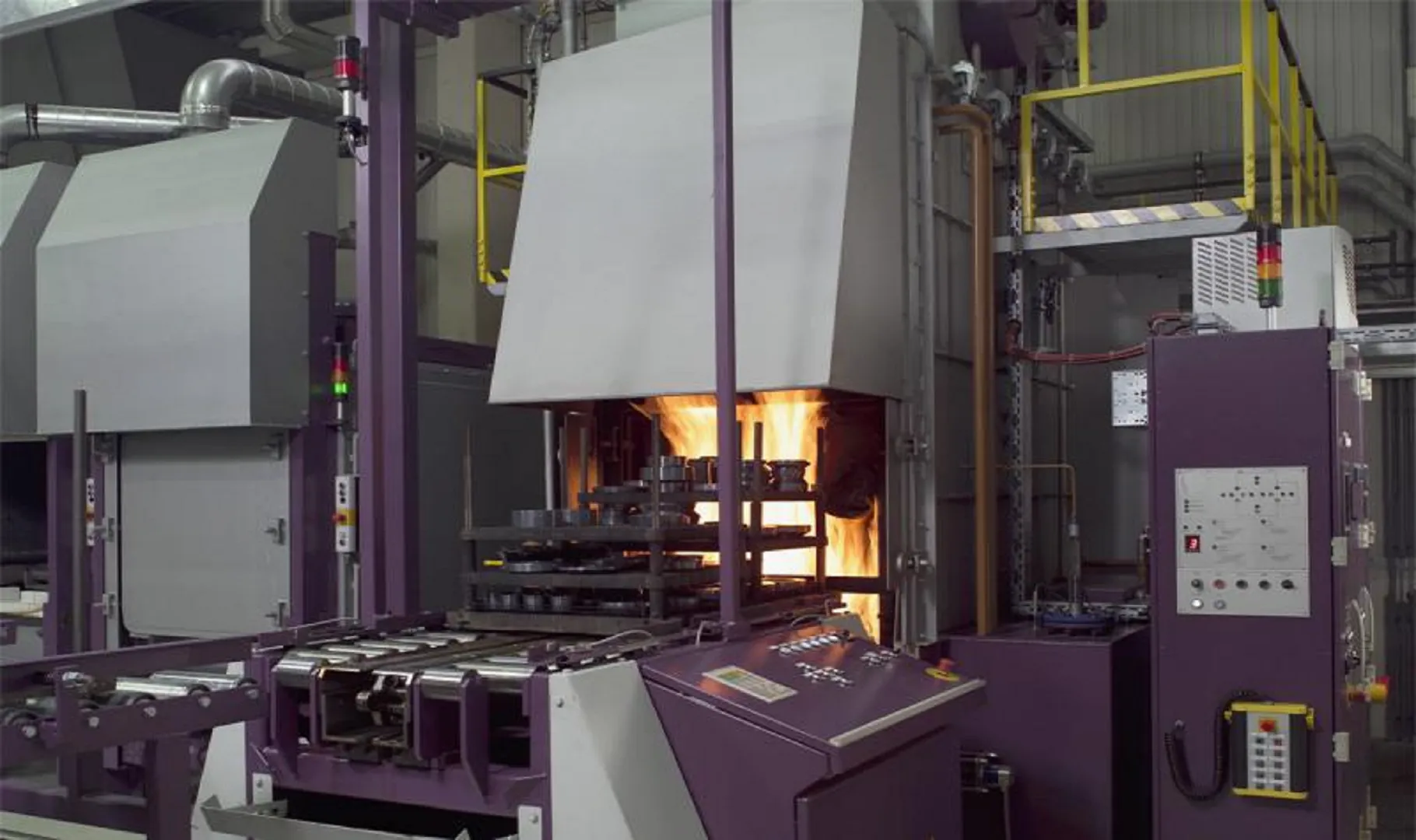

Case hardening is a heat treatment process used to harden the surface (or case) of a metal while maintaining a softer, ductile core. This technique is often applied to steels to enhance wear resistance, strength, and durability without sacrificing the toughness of the interior.

Process Overview :

-

1. Heating

The metal (usually steel) is heated to a high temperature, typically in the range of 800-950°C (1472-1742°F), in the presence of a carbon or nitrogen-rich environment.

-

2. Carburizing or Nitriding:

○ Carburizing : The workpiece is exposed to a carbon-rich atmosphere (often a mixture of gases like methane or carbon monoxide) or a solid carbon source (like charcoal) during heating. This allows carbon to diffuse into the surface of the material.

○ Nitriding : The material is exposed to nitrogen-rich environments (such as ammonia gas or nitrogen gas), where nitrogen is absorbed by the surface.

○ Combination (Oxynitriding): In some cases, both carbon and nitrogen are introduced to improve the properties of the surface

-

3. Quenching :

After carburizing or nitriding, the metal is rapidly cooled (quenched) in a liquid, usually oil or water, to lock in the hard surface layer. -

4. Tempering :

After quenching, the material may be reheated (tempered) to a lower temperature to reduce internal stresses and improve toughness. This is especially important if a high-carbon layer is formed, as it can be brittle without tempering. -

5. Finishing :

The case-hardened part may undergo finishing processes like grinding, polishing, or machining to achieve the desired surface quality.

Types of Case Hardening

-

1. Carburizing :

○ The process of adding carbon to the surface of low-carbon steel by heating it in a carbon-rich environment. This allows the surface to become very hard while maintaining the toughness of the core. -

2. Nitriding :

○ Involves introducing nitrogen into the surface of the steel, which forms hard nitrides. This process is usually done at a lower temperature than carburizing and is often used for steels that require high wear resistance and corrosion resistance. -

3. Carbonitriding: :

○ A variation of carburizing, where both carbon and nitrogen are introduced into the surface, improving both the hardness and fatigue resistance of the material. -

4. Induction Hardening:

○ A type of case hardening where an electric current is used to heat the surface of a part, which is then quickly quenched. This is localized to specific areas, making it ideal for parts with localized wear resistance needs.

Benefits of Case Hardening

- Enhanced Surface Hardness

- Retained Ductility

- Improved Fatigue Resistance

- Increased Durability

- Customization

The outer layer becomes significantly harder than the core, improving wear resistance.

The core of the material remains soft and tough, preventing brittleness.

The hardened surface helps improve the part's resistance to fatigue failure.

Parts are more resistant to wear, corrosion, and other forms of degradation.

The depth and hardness of the hardened case can be controlled by adjusting the process parameters, offering flexibility for different applications.

Applications of Case Hardening

Case hardening is commonly used in industries where parts are subjected to high wear, stress, and corrosion. Some typical applications include:

-

Automotive

Gears, camshafts, crankshafts, and other high-stress components.

-

Aerospace

Turbine blades, gears, and shafts that require both strength and resistance to wear.

-

Machinery

Bearings, shafts, and other rotating components in machines.

-

Tooling

Cutting tools, dies, and punches, where the hardened surface enhances tool life.