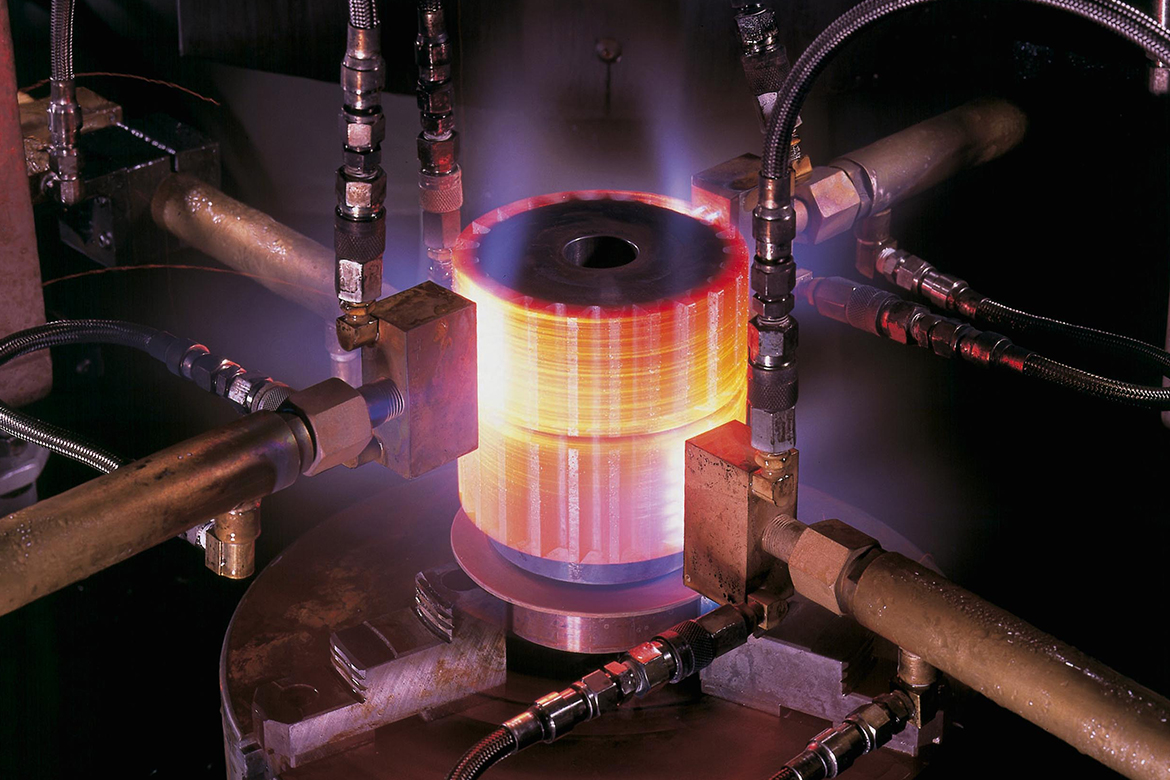

Induction Hardening

Induction hardening is a surface-hardening process that uses electromagnetic induction to heat the surface of a metal component rapidly, followed by quenching to increase hardness. It enhances wear resistance, fatigue strength, and durability without affecting the toughness of the core.

1. How Induction Hardening Works

Step-by-Step Process

-

1. Electromagnetic Induction Heating

○ An alternating current (AC) passes through a copper induction coil.

○ This creates a magnetic field, inducing eddy currents in the workpiece.

○ The metal surface is rapidly heated to the hardening temperature (800–1000°C). -

2. Austenitization

○ At high temperatures, the steel structure transforms into austenite (soft phase).

-

3. Quenching

○ The heated surface is quickly cooled using water, oil, or polymer quenching.

○ This causes the austenite to transform into martensite (hard phase). -

4. Tempering (Optional)

○ To reduce brittleness, the part can be reheated to 150–300°C for controlled hardness.

2. Advantages of Induction Hardening

✅ Selective Hardening – Only specific areas of a part are

hardened.

✅ Fast Process – Heat treatment takes only seconds to

minutes.

✅ Minimal Distortion – The core remains unaffected, reducing

warping.

✅ Improved Wear Resistance – Extends the life of components.

✅ Energy Efficient – Direct heating reduces energy

consumption.

✅ Automated & Repeatable – Ideal for mass production.

3. Applications of Induction Hardening

🔹 Automotive Industry – Crankshafts, camshafts, gears,

axles.

🔹 Aerospace Components – Landing gear, turbine shafts.

🔹 Machine Tools – Spindles, bearings, cutting edges.

🔹 Railway Industry – Train wheels, rails, shafts.

🔹 Defense & Firearms – Barrels, slides, hammer surfaces.

4. Types of Induction Hardening

A. Single-Shot Induction Hardening

● The entire workpiece is hardened in one heating cycle.

● Used for small or simple-shaped components.

B. Progressive (Scanning) Induction Hardening

● The part is moved through the coil to harden specific sections.

● Used for long parts like shafts & axles.

5. Induction Hardening vs. Other Hardening Methods

| Feature | Induction Hardening | Flame Hardening | Carburizing | Nitriding |

|---|---|---|---|---|

| Heating Method | Electromagnetic Induction | Direct Flame | Carbon Diffusion | Nitrogen Diffusion |

| Speed | Fast (Seconds-Minutes) | Slow | Slow (Hours) | Very Slow (10–100 hours) |

| Surface Hardness | 50–65 HRC | 45–55 HRC | 55–62 HRC | 55–70 HRC |

| Distortion | Low | High | Medium | Very Low |

| Best for | Shafts, gears, camshafts | Large machine parts | Gears, bearings | Aerospace, high-precision tools |

6. Induction Hardening Depth & Hardness

| Material | Hardening Depth | Typical Hardness (HRC) |

|---|---|---|

| 1045 Steel | 1–3 mm | 50–55 HRC |

| 4140 Alloy Steel | 2–5 mm | 55–60 HRC |

| 4340 Alloy Steel | 2–6 mm | 55-62 HRC |

| Ductile Iron | 1-4 mm | 45-50 HRC |